Mostly use for crunching riveting clamping bending marking purpose.

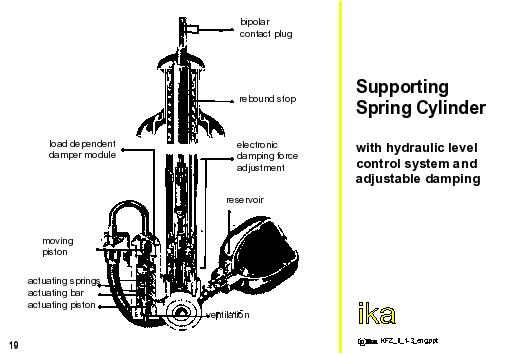

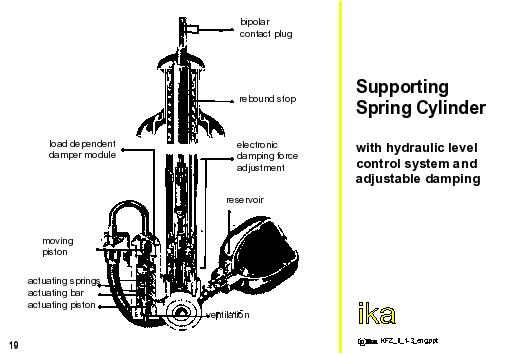

Hydro pneumatic spring cylinder.

In a pneumatic cylinder the pressure that comes from a manual pump or external compressor moves the piston that is inside the hollow cylinder.

The only difference in the way a hydraulic cylinder works is that an unyielding liquid causes the cylinder to move.

Hydropneumatic suspension is a type of motor vehicle suspension system designed by paul magès invented by citroën and fitted to citroën cars as well as being used under licence by other car manufacturers notably rolls royce maserati and peugeot.

The maximum spring compression pushes back on the piston and the hydraulic fluid exits the cylinder and returns to its starting position.

Hydro pneumatic cylinders are separately power units so that can be purchased separately and further spm prepares in to larger systems.

Compact and easy to install for clamping holding and riveting applications.

Air air air hydraulic close hole punch cylinders hole punch cylinders original line hole punch close lockout tagout valves.

A spring back force or fluid supply returns the piston to its original position.

The increase in pressure creates a linear force.

It was also used on berliet trucks and has more recently been used on mercedes benz cars where it is known as active body control.

Therefore you can consider the basic designs of any of our pneumatic and hydraulic cylinder series for spring design in your application from the 3 4 diameter bore on up to our largest bore including the valve actuation cylinder and the all stainless steel cylinder construction.

The bottom image is a double acting cylinder where fluid.

More basic and cost effective than double acting cylinders these single acting cylinders exert force in one direction and have a spring to return the rod to its original position.

These cylinder are widely use in spm in automobile plastic industries and many more.

The toyota soarer uzz32 limited was fitted with a fully integrated four wheel steering and a complex.

A pneumatic cylinder with a double acting operation has two ports that use air to extend and retract a rod creating stroking actions that perform work in both directions of movement.

Mechanical spring cylinders either use a spring to extend so the cylinder will stroke to the fully extended position when pressure pneumatic or hydraulic is removed from the rod end port or retract.

Short stroke clamping air cylinders also known as air clamps these cylinders are used to apply force in holding applications.

The vb actuator is a single acting pneumatic clamp cylinder with built in oleo pneumatic intensifier producing a force up to 2100 dan.