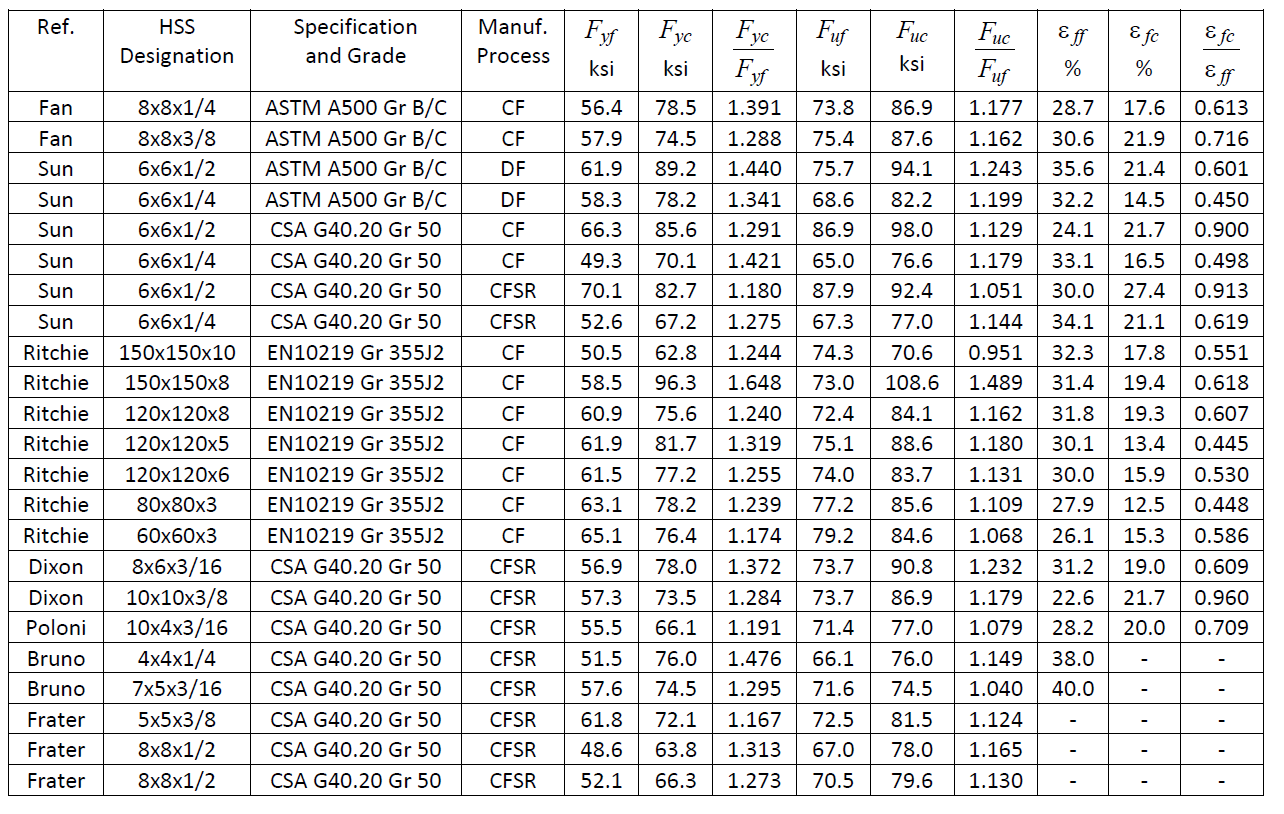

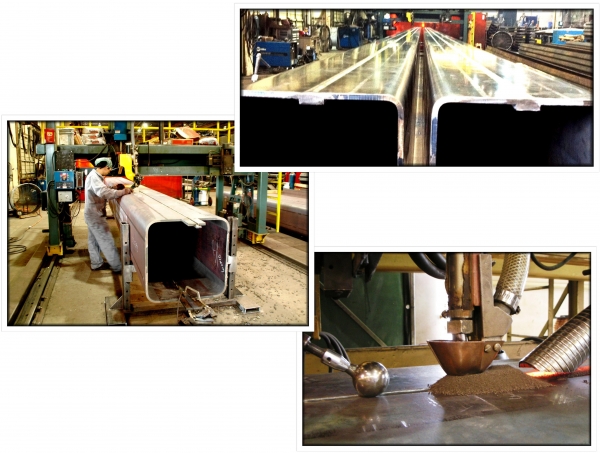

Hss manufacturing methods the transformation of steel strip into hollow structural sections hss is the result of a series of operations including formi ng welding and sizing.

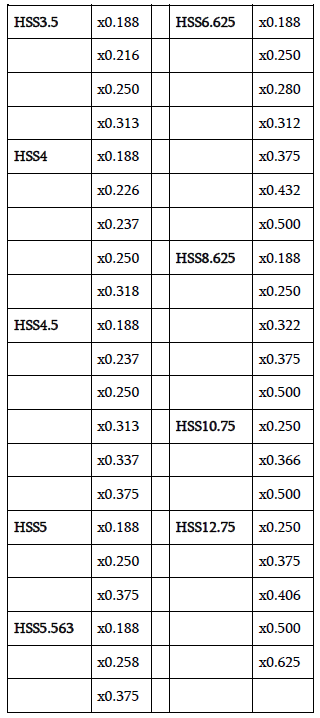

Hss tube steel dimensions.

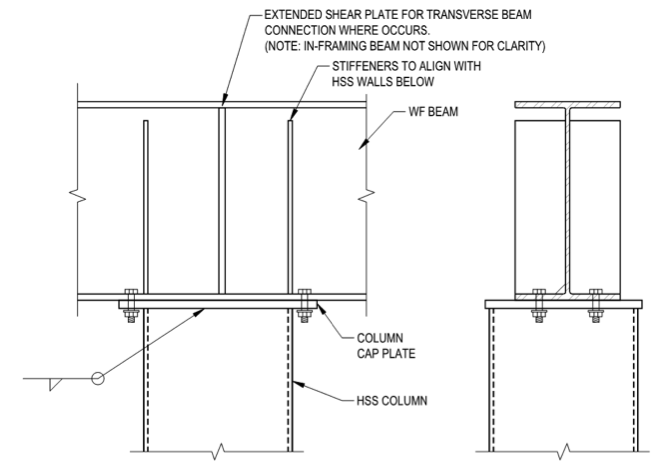

Pipes are also manufactured to an exterior tolerance albeit to a different standard the corners of hss are heavily rounded having a.

Additionally astm a500 hss can be obtained in many more sizes with periphery not exceeding 64 in.

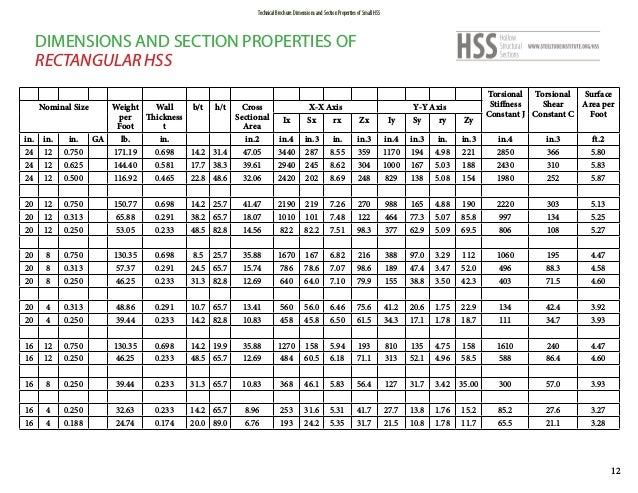

Square hollow structural sections hss weight cross sectional area moments of inertia imperial units steel angles equal legs dimensions and static parameters of steel angles with equal legs metric units.

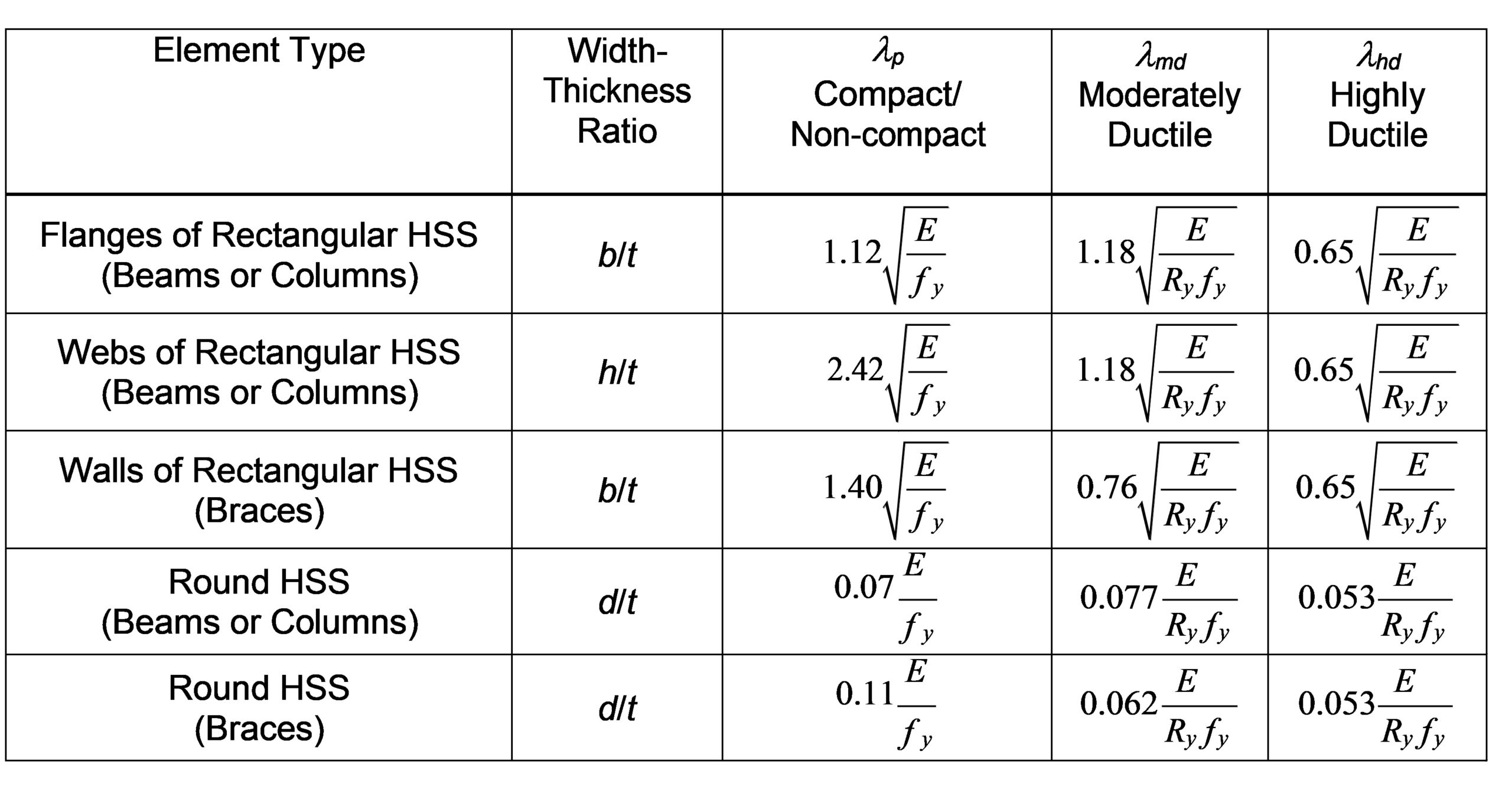

Round hss are usually astm a500 grade c fy 46 ksi.

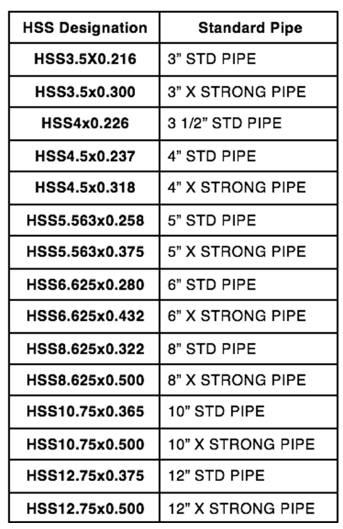

For example an hss 6 625 0 280 has the same dimensional properties as a pipe 6 std.

Circular hss are sometimes mistakenly called steel pipe although true steel pipe is actually dimensioned and classed differently from hss.

They are available in cross sections matching each of the cross sections for astm a53 grade b steel pipe.

These methods are described below.

Currently three methods are being used in north america for the manufacture of hss.

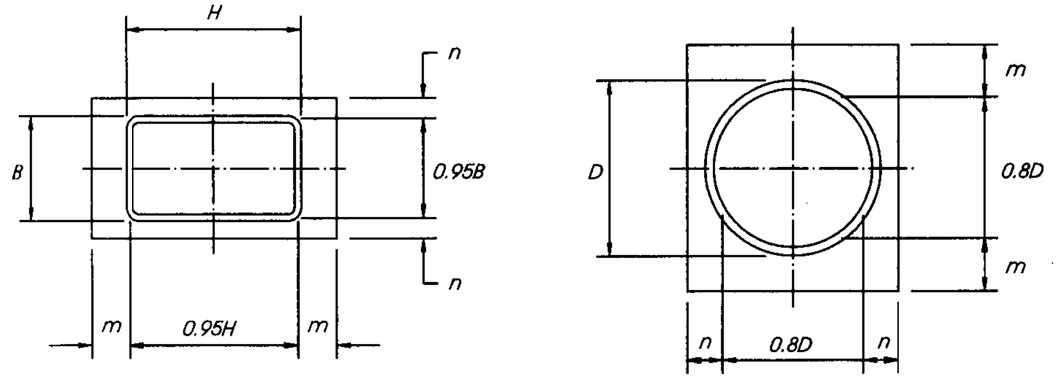

H height w width t wall thickness i area moment of inertia s elastic section modulus.

The tube s final dimensions.

Rectangle structural tube per.

Steel square tube is widely used in industrial maintenance agricultural implements transportation equipment truck beds trailers frames etc.

Hss dimensions are based on exterior dimensions of the profile.